The Unexpected Challenge of Global Machine Integration

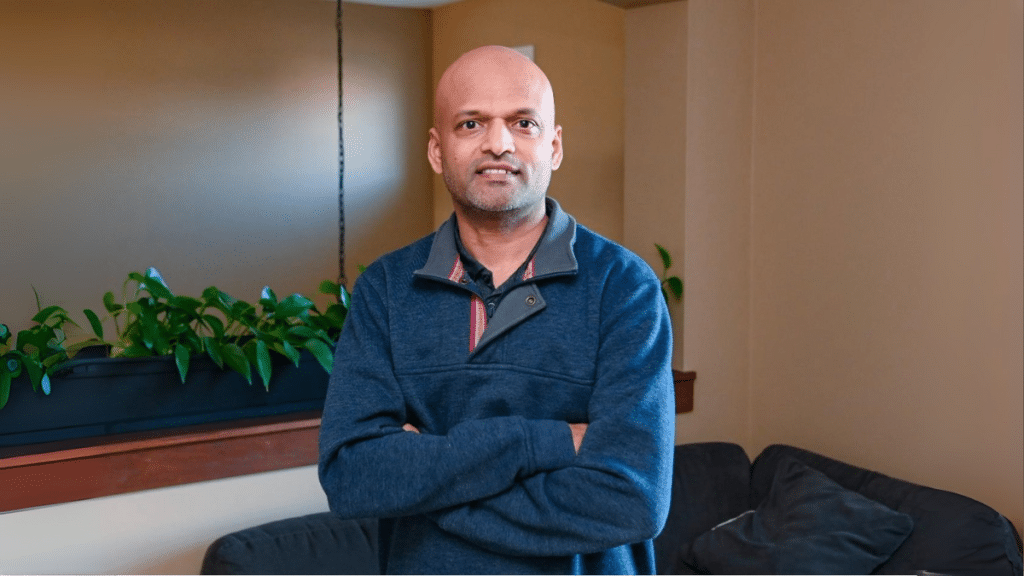

In an adjoined age where production covers continents, the capcapacity towards incorporate devices coming from varied beginnings right in to a combined manufacturing atmosphere is actually important. Ravikumar Palanichamy, a professional in production bodies combination, sheds illumination on the requirement for "translators"—not simply individual however technological—to connect the splits in contemporary manufacturing facilities.

In an adjoined age where production covers continents, the capcapacity towards incorporate devices coming from varied beginnings right in to a combined manufacturing atmosphere is actually important. Ravikumar Palanichamy, a professional in production bodies combination, sheds illumination on the requirement for "translators"—not simply individual however technological—to connect the splits in contemporary manufacturing facilities.

The Unexpected Challenge of Global Machine Integration

Making use of his expertise, Palanichamy discusses that markets like home window production progressively depend on specific particular niche market devices sourced worldwide. Devices developed in various areas should integrate perfectly along with Production Implementation Bodies (MES) as well as Business Source Preparation (ERP) systems industrialized somewhere else. Soft body interaction is actually important for effective production; nevertheless, incompatible interaction procedures, differing information styles, as well as foreign language obstacles in paperwork frequently interrupt this combination. As an architect of these complicated bodies, Palanichamy highlights the require for comprehensive body comprehending, standardization, fostering of global procedures (e.g., OPC UA), middleware services, as well as multilingual educating towards reduce these combination difficulties.

Woman says Zou raped her hours before other attack

Palanichamy's focus on producing typical interaction systems for disparate bodies has actually shown crucial, especially throughout the updating or even setup of brand-brand new setting up collections. As an essential factor, he has actually developed systems towards guarantee interoperability amongst devices, MES, as well as ERP bodies coming from different nations. His function has actually assisted in effective setups as well as procedures of worldwide equipment, enhancing production line effectiveness. This consists of coordinating accurate information exchanges along with providers towards guarantee suitable components manufacturing as well as leveraging standard procedures (e.g., OPC UA) as well as extensive body mapping towards reduce interruptions, improve manufacturing dependability, as well as allow scalable procedures.

Executing standard interaction structures has actually considerably decreased sustain opportunity for the MES. Shut partnership along with MES as well as setting up device designers reduces manufacturing downtime, guaranteeing functional connection. Quantitatively, Palanichamy's efforts have actually steered effectiveness increases of 3% towards 9%. This efficiency boost certainly not just decreased sustain opportunities for MES groups however likewise added to considerable labor expense cost financial savings as well as sustained scalable production procedures, aligning carefully along with Market 4.0 imperatives.

Komentar

Posting Komentar